Scannning MEMS Mirrors Cutting edge technology

Those mirrors are designed for laser display devices and laser sensor devices, with the capability of Raster and Lissajous scanning modes. The scanning mirror design is very flexible and comes with different optical coatings.

- Mirror size: 1.1 x 1mm

- Fov: 45x20

- Resolution: 1280x480

- Frequency: 10kHz

- Actuation methods – Electrostatic (ES) and Electromagnetic (EM)

- Sensing method – Electrostatic (ES)

- Scanning modes: Raster scanning, Lissajous scanning

- High and diversified Reflective optical Coating on MEMS mirrors

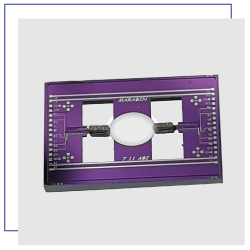

- Flexible Optical Packaging for the MEMS mirrors

Those mirrors are designed for high-end laser displays, utilizing Raster scanning mode. Those mirrors are characterized by a large FoV and high frequency, resulting in high refresh rates and high resolution capabilities.

- Mirror size: 1.1 x 1mm

- Actuation methods – Electrostatic (ES) and Electromagnetic (EM)

- Sensing method – Electrostatic (ES)

- Scanning modes: Raster

- Large FOV

- High refresh mode

- Full HD resolution

- Both progressive and interlace scanning

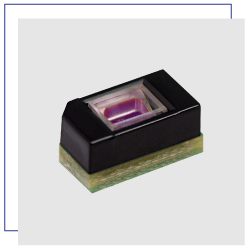

MEMS 1D SCANNING MIRROR

This mirror is designed for laser sensor devices and capable of Oscillations, Ramp and Point-to-Point scanning modes.

The MEMS scanning mirror design is very robust and is available as a single mirror for 1D scanners or a set of 2 mirrors for 2D scanners.

- Mirror size: 1.3 x 1.5mm

- Actuation method – Electromagnetic (EM)

- Sensing method – Electrostatic (ES)

- Scanning modes – Oscillations, Ramp, point to point, Other

- High and diversified Reflective optical Coating on MEMS mirrors

- Flexible optical package for MEMS laser scanning mirrors

MEMS based micro-mirrors

for laser scanning devices,

Maradin MEMS based micro-mirrors are based on sophisticated silicon structures that enable the MEMS devices for large scanning angles, in multiple directions, at a very precise control using C-SOI technology.

The C-SOI technology makes use of multiple SOI wafers. These are patterned and bonded together to enable the 3D structure of the micro-mirrors.

Tiny actuators based on Electromagnetic and Electrostatic proprietary designs are implemented in the MEMS micro-mirrors, to induce its scanning rotation and different scanning modes.

Capacitive sensors, carved into the silicon, enable the sensing activity of the MEMS micro-mirror movement and ensure high precision operation in a variety of scanning modes.

Special optical coating applied to the MEMS mirror surface enables the highest reflectivity for laser projection without compromising on mirror flatness.

FAQs MEMS Mirrors :

Yes. They are created in a special facility called a MEMS Fab. The MEMS Fab is very similar to a standard semi-conductor manufacturing facility. But instead of using surface micro-machining, where the device is built layer by layer, MEMS micro-mirrors are usually manufactured using bulk micro-machining in which the MEMS is etched from a single Silicon layer.

Yes. MEMS micro-mirrors are made of a single crystal Silicon bulk item. It’s a brittle material that can break if very high stress is applied to the micro-mirror structure. To avoid such breakage, MEMS micro-mirrors are therefore designed to withstand much higher stress when operated.

Yes. Combining two 1D micro-mirrors (2x1D) will provide a 2D laser scanning function similar to Galvo scanners. However, you need to make sure that the second micro-mirror is large enough to obtain the first scanning angles.

For a 2D mirror scanner, we use a gimballed architecture, in which the first rotating angle is achieved within a rotating structure (i.e., the gimbal) of the second scanning direction. For example, the horizontal scan is done using a gimbal that rotates in the vertical scanning direction. For this result, we need a compact actuator that can rotate together with the gimbal, so we choose an electrostatic actuator for the fast axis. However the second scanning direction needs a powerful actuator that rotates the entire gimbal. In this case we choose an electromagnetic actuator. The combination of both actuation methods, forms a very powerful laser scanner device.