Review of the Main Advantages of MEMS Technology

The beginning of the 21st century was about the rapid growth of the MEMS market. Microelectromechanical technologies hit most industries and transformed the vision of modern manufacturers and entrepreneurs. The steady development is observed and now. More and more companies are interested in innovative tech solutions based on MEMS.

There is a range of reasons for the popularity of microelectromechanical technology popularity around the world. MEMS laser projector models, different sensors, a blend of MEMS-based and LiDAR devices, and other units simplify the business and industrial processes while bringing more accurate measurements and automation of manufacturing, driving, estimating, etc.

One of the main advantages microelectromechanical technology provides to present-day market players and industries’ decision-makers is the opportunity to undertake different tasks at a micro-scale. This benefit is not the only one. There are many advantageous features concerning MEMS to take into consideration.

Unique Benefits of MEMS: Micro-Scale Processes, Compact Sensor Size, Improved Optical Performance

It seems that the Nobel Prize given to scientists H. Rohrer and G. Binnig in 1986 was the recent award. But from the end of the 20th century and up to the beginning of the 21st there are many changes to take into account.

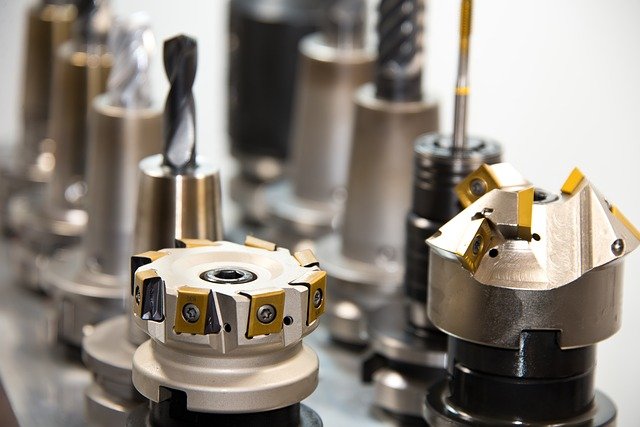

Besides the innovative scanning tunneling microscope invented by IBM specialists, there are plenty of tech units based on the microelectromechanical technology today:

2D MEMS scanning mirror devices;

Near-field optical microscopes;

MEMS-based sensors and gyroscopes;

Handphones;

Micro-grippers;

Micro-tips, microphones, etc.

What Advantages Do MEMS Bring?

Speaking about the main benefits of the MEMS technology, it was mentioned the capability to undertake micro-scale tasks. This is about microsurgery, measurements, and other tasks that were impossible in the 20th century. Additionally, tech units based on microelectromechanical systems are compact and lightweight in comparison with the former technical solutions.

For example, a gyroscope that weighs more than several hundred kilos can be replaced with the small one that contains a MEMS chip and weighs about 100 g. It means that all complex installations and complicated approaches can be transformed with microelectromechanical systems. Some specialists are thankful to MEMS manufacturers for the opportunity to use optical and other tech solutions in the hard-to-reach places:

Forests;

Tunnels;

Undersea, etc.

The micro world is the new-generation environment with new tools and devices that simplify many scientific tasks and technological processes via MEMS. Microelectromechanical systems are about convenience (compact size, light-weight), flexibility (possibility to use tech units in hard-to-reach places), and the development of microenvironments.

The performance of optical and other features is improved as well with MEMS (like scanning mirrors and projectors). Microelectromechanical systems promote the exclusive electro-osmotic effect and promote the progress of quantum mechanics. Additionally, the fact of miniaturization of the MEMS-based tech units is the way to reduce development, testing, packaging, transportation, and maintenance costs that is critical for the MEMS market niche today.

The present-day market players are interested to replace costlier and bulkier devices with new-gen units that require fewer expenditures and arrangements. For example, the former airbag sensors can become things of the past with the MEMS accelerometers and sensors.

The same story is about MEMS-based handphones that are likely to turn into a win-win solution in comparison with previous models of game controllers and digital cameras with poor image stabilization properties.

It is expected that new MEMS tech units will solve the problem with self-testing and self-simulation. The automated stage of the development of new models will reduce even more costs. At the same time, non-MEMS sensors will be replaced with microelectromechanical system-based ones that do not depend on magnetic fields, extreme weather conditions, and other external factors.